High-speed Intelligent System for Waste Sorting

The Bionic Design and Learning Lab led by Dr. Chaoyang Song has developed a high-speed intelligent system. This system has broad commercial prospects and application value, especially in scenarios such as garbage sorting and agricultural sorting. We conducted a commercial transformation attempt at the system and won the bronze prize in the 13th “Challenge Cup” Guangdong University Student Entrepreneurship Plan Competition.

Background

The concept of sustainable development, the judgment that lucid waters and lush mountains are invaluable assets, and the newly revised law on prevention and control of environmental pollution by solid waste law all highlight the important position of ecological civilization construction, and waste classification is an important part of ecological civilization construction. In response to the call of ecological civilization construction and the development needs of the times, the team proposed the design scheme of high-speed intelligent waste sorting system, which uses modern technology to contribute to renewable resources recycling and ecological civilization.

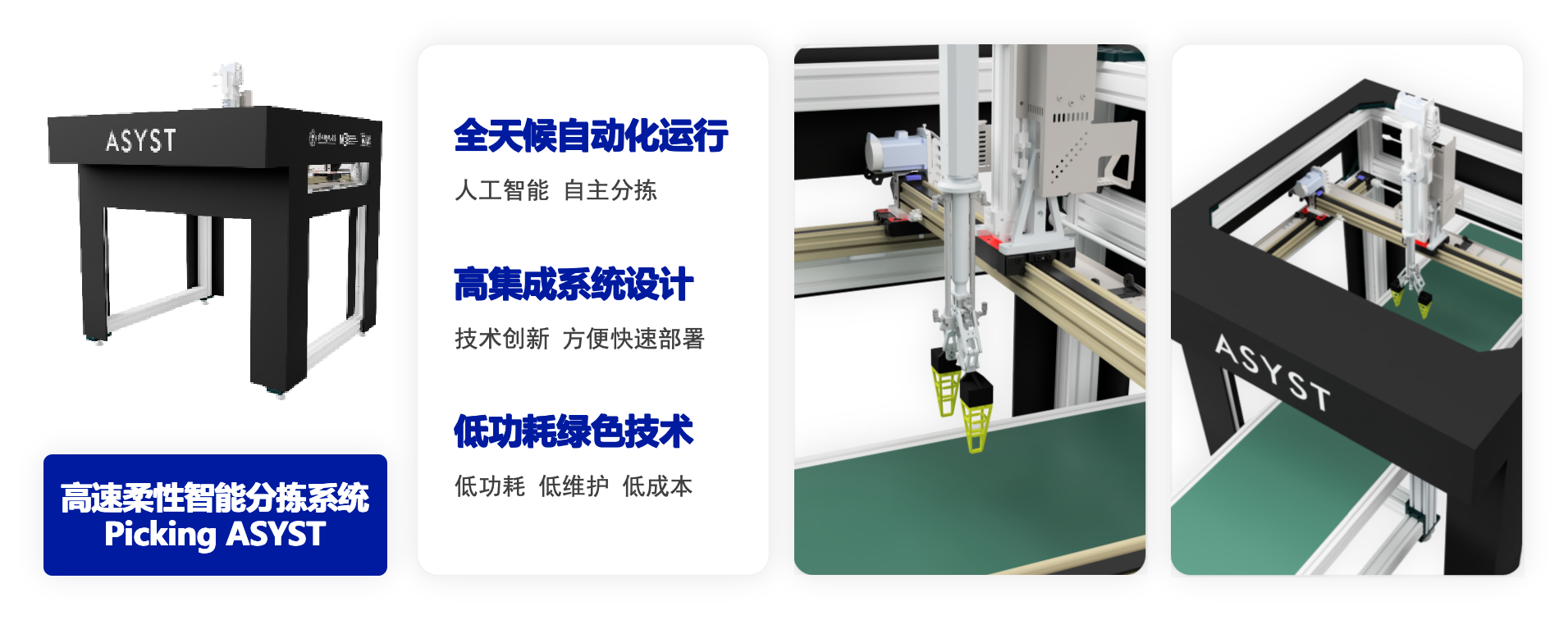

ASYST Series Products

Picking ASYST is an high-speed intelligent system for waste identification and sorting. It combines artificial intelligence with high-speed sorting to realize all-weather autonomous operation. The system integrates a number of innovative technologies, adopts the self-developed high-speed industrial robot ASYST Robot, the self-designed adaptive flexible gripper ASYST Picker and the intelligent algrithm ASYST Brain, which can help users improve the speed of waste identification and sorting while maintaining the high accuracy of various items, thus replacing manual sorting and increasing profits.

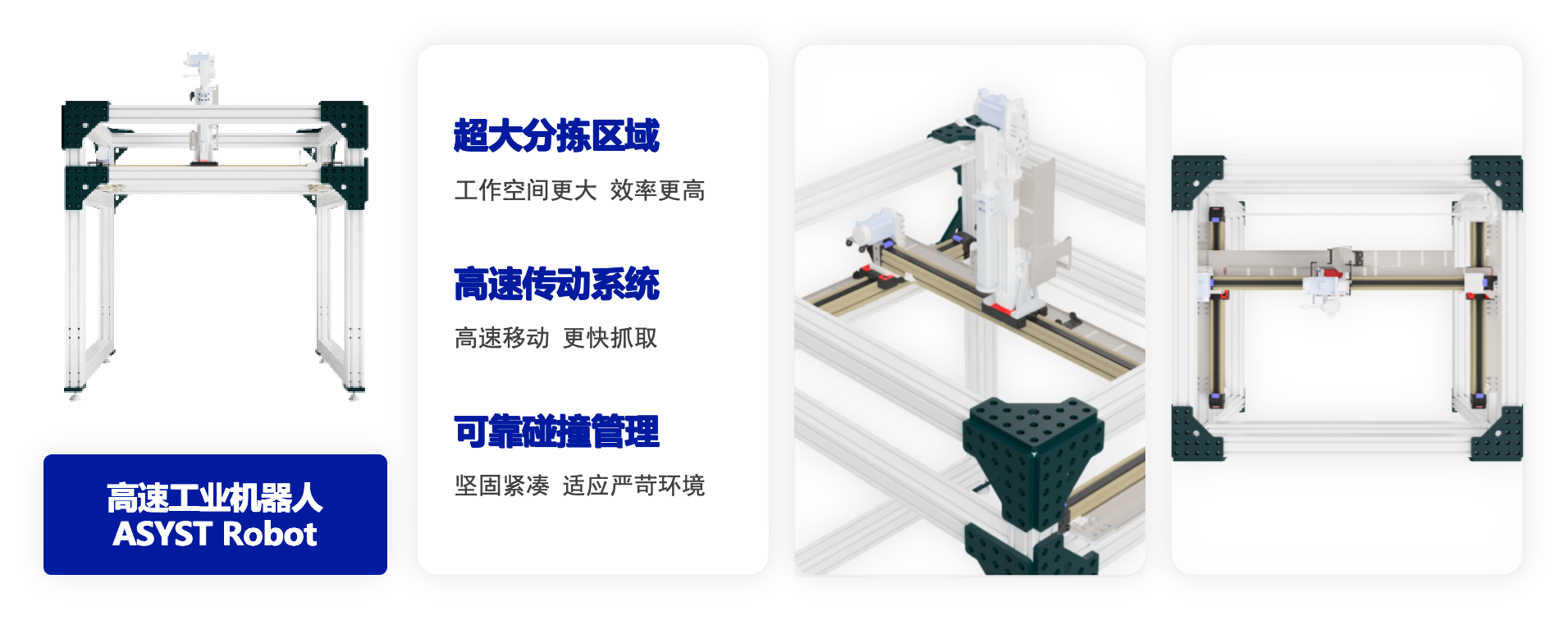

ASYST Robot can realize the maximum sorting area within the conveyor belt. The rectangular working area allows it to have more time to track and capture the target object in a larger space, and the working space completely covers the conveyor belt, which is more efficient. At the same time, ASYST Robot has reliable collision management and can adapt to the harsh garbage sorting environment. Its solid and compact structural frame, coupled with flexible gripper design, allows the base station to freely collide and avoid damage when encountering unexpected objects, effectively improving the safety of the equipment.

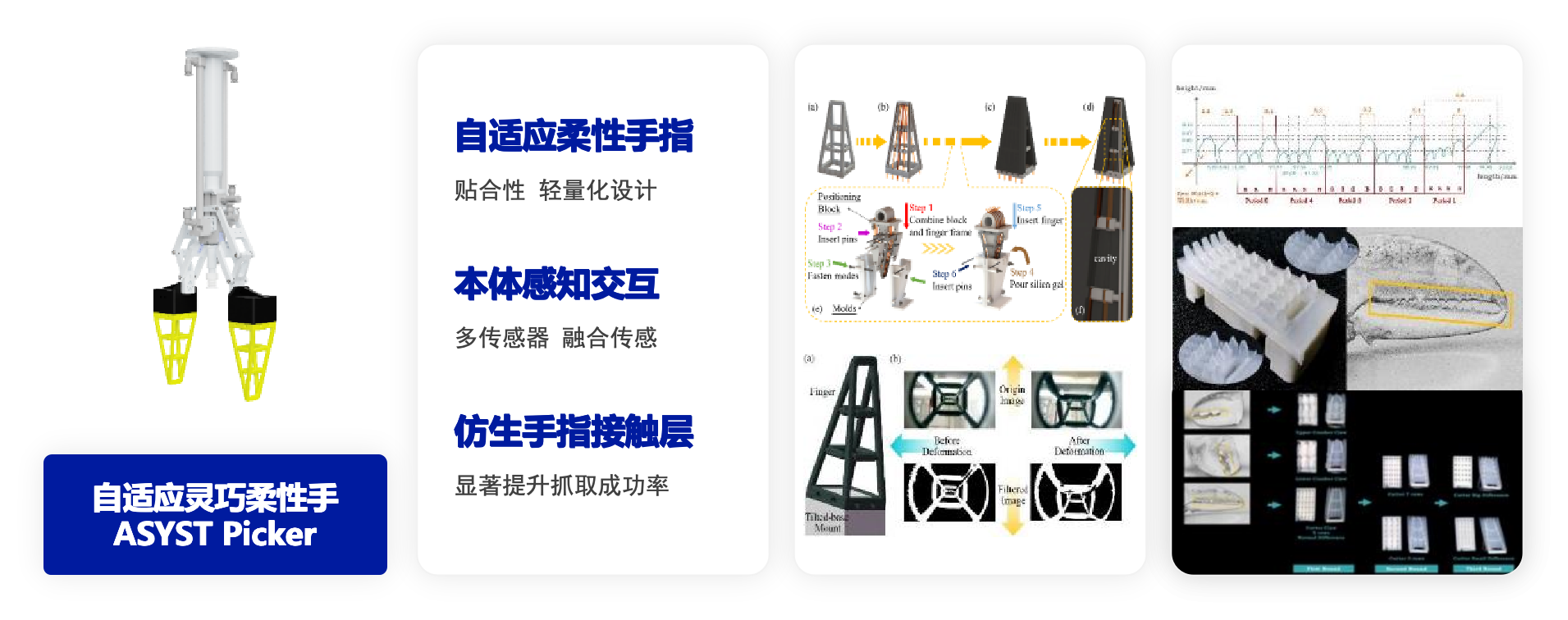

ASYST Picker is a high-precision robot end effector developed as a complete set. It adopts modular design and is composed of base, power mechanism, suction cup and fingers. It is easy to replace and maintain, and effectively solves the pain points of high-precision sensing gripper, which are expensive and difficult to maintain. ASYST Picker has two capture modes of suction cup and finger clamping, which can be automatically selected according to the characteristics of the target object to improve the capture efficiency: the suction cup has strong grip force and fast speed, and can be used to capture objects with regular shape and large mass; The finger has a flexible structure with differential stiffness, and adopts a bionic contact layer design to enhance the coating effect of the target object, which has an obvious effect on improving the success rate of grasping complex structural objects. ASYST Picker is also equipped with a multi-sensor fusion method with optical fiber sensors, vision sensors and other sensors. It can effectively improve the capture accuracy and efficiency, which is convenient for high-speed and stable capture of various items in the garbage sorting scene.

ASYST Brain uses the self-developed waste recognition and classification algorithm, together with visual sensors, thermal imaging sensors and other sensor arrays, which can realize the millisecond tracking recognition and grasp decision-making of the detected object. In order to adapt to the huge data in various types of waste sorting scenarios, ASYST Brain adopts the “cloud-edge collaboration”. During the working process, the system can automatically record the object feature data and upload it to the cloud server. Relying on the powerful cloud computing power, the cloud brain can analyze and learn the massive data collected, continuously optimize the existing identification network, and regularly update it to edge ASYST Brain to figure out complex identification and classification challenges.

Picking ASYST adopts modular design, which makes it possible to customize the production line according to business needs, and is expected to bring a simple, fast and professional user experience from design to deployment. On the self-developed visual design platform Design ASYST, users can select the corresponding components and functions according to their own business needs, combined with the professional guidance and suggestions of platform engineers, to obtain the exclusive system design. In addition, the self-developed visual programming platform Machine ASYST greatly reduces the programming threshold for users, and can quickly control the designed system and complete platform simulation and program debugging without code programming. After the completion of hardware design and software debugging, users can directly place orders for production on the platform and supervise the order process. After receiving the product, users can easily complete the assembly and system field debugging, or choose engineers to provide on-site service. After the final system test, Picking ASYST can be online.